Sandblasting Cabinet Manufacturer in India

Cabinet Type Sandblasting Machine or Sandblasting cabinet gives a large sort of application functions. Our sandblasting machine comes in an in depth vary of sizes and is employed with nearly any dry abrasive blast media. The blasting of enormous areas or batches of tiny elements are simply achieved with these systems.

Sandblasting Cabinets are ideal for lower volume applications wherever price may be a issue. These systems are accessible during a wide range of sizes to accommodate nearly any size half and are designed for faster blasting furthermore as a lot of regular usage each of those vogue cabinets can be tailored and changed to fulfill the desired project specifications.

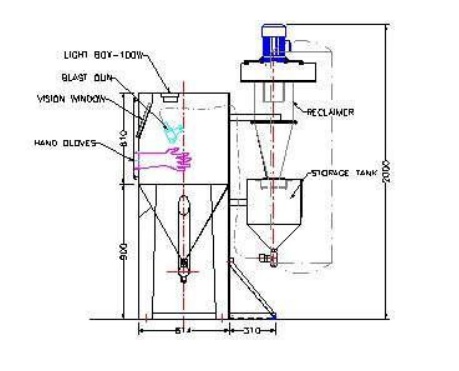

The cabinet sandblasting machine operates on the suction principle of abrasive blasting. The vacuum created by the compressed air issuing out of the injector and re-entering to the nozzle, lifts the abrasive from its storage tank to the re-entry point at the nozzle in the blast gun. The lifted abrasive gets mixed with the compressed air in the blast gun to strike the job to be cleaned. The operator takes one lot inside the cabinet and during blasting operation holds one job at a time and manually blasts clean the job. After cleaning, operator keeps the blast cleaned job in the cabinet itself & lifts the other job for blast cleaning. After cleaning, job can be air washed with a air blow gun provided. Used abrasive and dust created during blasting are sucked through a flexible suction hose to re-claimer where usable grit is reclaimed and collected in a storage tank for recycling and the dust is carried ahead and collected inside fabric bag fitted at the outlet of the exhaust fan and clean air is discharged into the atmosphere

BENEFITS of Cabinet Type sandblasting machine:

- Quick and economical Surface Modification

- Cabinet type sand blasting for a spread of Applications

- Both Economical and serious Duty Systems

- Large and tiny elements process

- Manual, Semi-Automated and Fully-Automated choices accessible

- Continuous Processing; Flow-Through Production

Working demo video of our Cabinet Sand Blasting Machine

Complete guide toSand Blasting Machine Types and Prices in India

Cabinet type sand blasting machine is far more helpful for the surface preparation. During this operation of a sandblasting cabinet, the cyclone separation system and dirt removal system, the extractor can separate the abrasive from a bust. The dirt removal system of this technology will handle and collect emit useless dirt, dirt removing impact of excellent cut back the price of abrasive and improve the potency of virtually each style of the surfaces. the simplest a part of this machine, it’s environmentally friendly, at the time of the operation there’ll be no pollution at your area.

Blasting Media:

APPLICATIONS OF A SANDBLASTING CABINET:

- Peening

- Cleaning

- Stripping

- Scale Removal

- Deflashing

- Rust Removal

- Surface Preparation For Coating

他re are somebasic steps to sandblasting inside a cabinet machine.

Paint Removal Cabinet Sand Blasting Machine Video

USES OF A CABINET TYPE SANDBLASTING MACHINE:

- Surface For Coatings Application

- Machine Mark Removal

- Rust Removal and improvement

- Auto and Truck Restoration

Working of a Sand Blasting Machine

Concrete Batching Plant Manufacturer in India

Installation of Blasting Machines in India

Call us immediately for Cabinet Type Sandblasting Machine in India or email us.Leading Sandblasting Cabinet manufacturer in India.

Ph: +91-0129-4902109 | Mob. 8882490101